Understanding Control Joints and Cold Joints in Concrete: Strengthening and Protecting Your Concrete Surfaces

Control Joints and Cold Joints in Concrete

When it comes to concrete, understanding the intricacies of its composition and installation is crucial for ensuring its longevity and strength. In this blog, we’ll delve into two essential aspects of concrete work: control joints and cold joints. As experts in the field, we at Sam The Concrete Man are committed to educating our clients and readers about these crucial components, ensuring that your concrete installations remain robust and durable.

What are Control Joints?

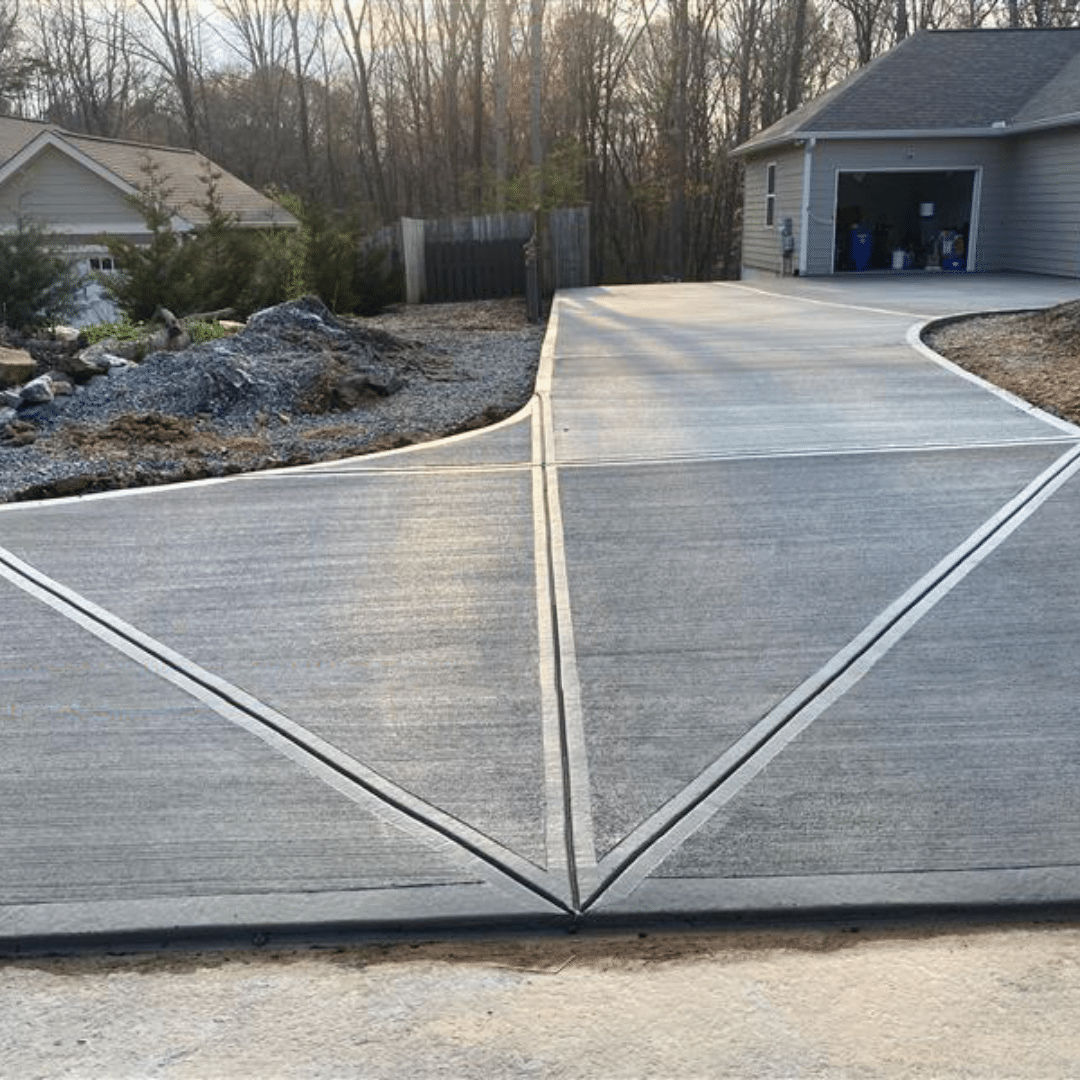

Control joints, also known as contraction joints, are planned cuts or grooves made in the surface of concrete slabs. These joints are strategically placed to control where the concrete should crack as it contracts during the curing process and throughout its life. Concrete, being a mix of cement, water, sand, and gravel, tends to shrink as it dries, which can lead to cracking.

Why are Control Joints Important?

The primary purpose of control joints is to guide the inevitable cracks along a predetermined path, thereby reducing random cracking, which can be unsightly and weaken the structural integrity of the slab. These joints are typically arranged in a grid pattern and should be spaced at regular intervals, calculated based on the thickness of the slab and the specific environmental conditions.

How do Control Joints Strengthen Concrete?

By controlling the location of these cracks, control joints help maintain the overall structural integrity of the concrete. They allow for movement caused by temperature changes, moisture expansion, and other environmental factors, without causing significant damage to the concrete. Properly placed control joints will effectively prevent random cracking and ensure that the concrete surface remains strong and intact for years.

What are Cold Joints?

Cold joints occur when two successive pours of concrete do not bond properly. This happens when the first batch of concrete starts to set before the next batch is added. Unlike control joints, cold joints are not planned and can be a point of weakness in a concrete structure.

Why are Cold Joints a Concern?

The main issue with cold joints is that they create a seam in the concrete where bonding between the two pours is insufficient. This can lead to water infiltration, reduced structural integrity, and can be a potential point of failure. Cold joints are particularly problematic in foundations and other structural elements where strength and continuity are paramount.

Avoiding and Addressing Cold Joints

To avoid cold joints, it’s crucial to plan the concrete pour carefully, ensuring that each batch is poured before the previous one begins to set. If a cold joint does occur, special techniques, such as using bonding agents or dowels, can be employed to ensure that the new and old concrete adheres properly, and the joint is strengthened.

Control Joints vs. Cold Joints: Key Differences

While both control joints and cold joints deal with the joining of concrete, they are fundamentally different in their nature and purpose. Control joints are intentional and beneficial, designed to manage cracking in a controlled manner. Cold joints, on the other hand, are unintended and can be detrimental, leading to potential weaknesses in the concrete structure.

Control Joints and Cold Joints

In conclusion, understanding and implementing control joints correctly is a vital part of any concrete installation, as they play a crucial role in maintaining the strength and appearance of the concrete. On the other hand, avoiding or properly addressing cold joints is essential for ensuring the structural integrity of the concrete.

At Sam The Concrete Man, we are dedicated to delivering high-quality concrete work that stands the test of time. By paying attention to these crucial details, we ensure that your concrete installations are not only aesthetically pleasing but also structurally sound and durable. Whether you’re planning a new project or looking to repair existing concrete work, understanding the importance of control joints and the risks of cold joints is key to making informed decisions for your property.

Remember, for any concrete-related needs, feel free to reach out to us for expert advice and quality service. Let us help you build a strong foundation for your future projects!